Celgard has a strong, active, and growing global patent portfolio and continuously advances separator design and functionality through significant research and development.

ADVANCED DEVELOPMENT STAGE:

Celgard® CoolStack™ Separators for Low Temperature Adhesion:

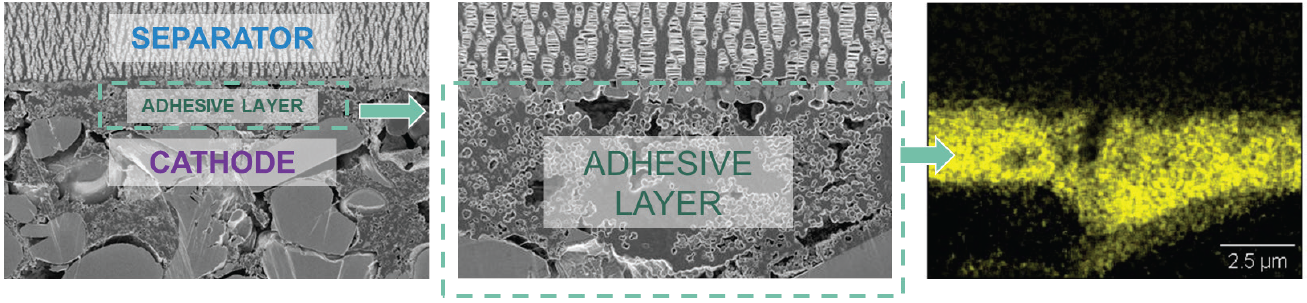

- Innovative adhesive coating formulation and technique that provides strong adhesion to electrodes at lower (< 60°C) temperatures

- Enables cell manufacturers to utilize high speed, low energy consumption "Stack / Z-fold" and "Press" cell assembly processes and realize significant savings in time and yield*

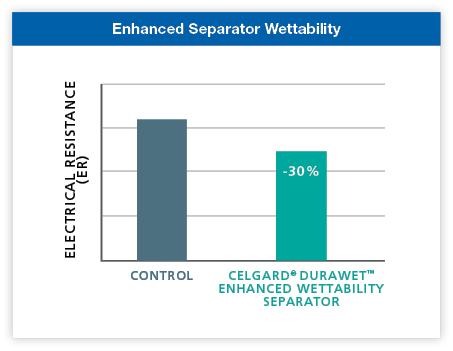

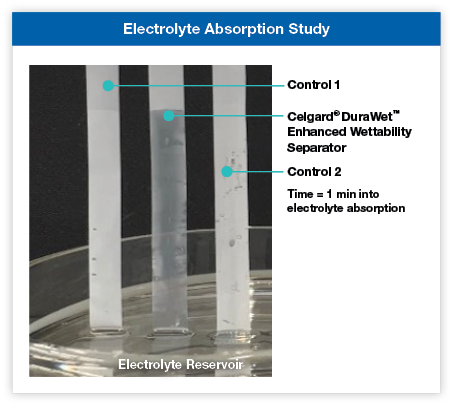

- Adhesive coating layer enhances wettability and lowers ER (electrical resistance) enabling longer battery life

*One heat press equipment manufacturer recorded at least 50 seconds in stack press time savings when using Celgard® CoolStack™ separators at 0.7-7 MPa vs. standard heat activated adhesive coated separators. They also estimated 2-4% in CAPEX savings could be achieved due to efficiencies in the cell assembly process.

Adhesive particles in Celgard® CoolStack™ Separators penetrate electrode pores, fusing with the cathode binder to further optimize the electrode-separator interface and improve the ionic conductivity, electrochemical stability and cycling of the cell

Contact Us to learn more about Celgard® CoolStack™ Separators for Low Temperature Adhesion.